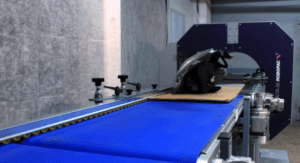

Wrappy is the automatic wrapping machine for car wheels and packages of different sizes, which are manually placed on a rotating plate and wrapped with stretch film.

There are 2 machine configuration:

- Box – for wrapping cardboard boxes,

- Tyres – for wrapping tires

Max weight of the object is 50 kg.

Other technical information:

- The standard diameter of the rotating plate: 600mm (option: 800mm);

- speed plates adjustable via an inverter from 4 to 18 rpm;

- constant speed of raising and lowering the carrier film;

- slow start and stop of wrapping;

- stopping in the initial position

- the standard maximum height of the wrapping 500 mm (optional: 1300mm);

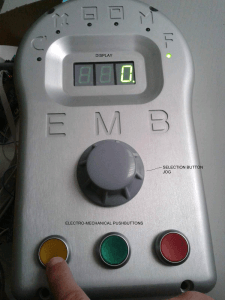

- various wrapping cycles: the manual / automatic, up / down, only up program with the pressure plate;

- integrated counter of daily wraps;

- adjusting the number of turns from 0 to 10;

- working height adjustable from 860mm – 1000mm;

- the height of the wrapping controlled by the photocell;

- integrated the standard wheels for easy movement of the machine in the room.