MASTERPLAT

The ECOPLAT series includes two different models, the distinguishing mark being a revolutionary control panel, which enables quick and easy use of various wrapping functions.

The ECOPLAT FRD control panel with the JOG and the icon screen makes it easier to approach the machine’s drives and easier to understand the control parameters.

FRD TICKET

The trolley with a mechanical brake on the return weld makes it easy to adjust the tightness.

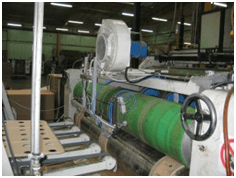

Automatic rotating ring rotating machine for horizontal winding, e.g. joining panels, furniture, doors, windows, these are long and unpaletized products of large dimensions.

With SPIROR FW machines, products of irregular shapes can also be rotated.

Rotary diameters: 1300, 1600, 2200, 2500 mm.

The maximum rate of rotation depends on the diameter. Spiror machines are designed to work in an automatic line.

There are 2 variants of the film carrier:

– MPS – patented – prestressing the film without motor STNAD. overload rate – 58% – 80% – 97%;

– Option: OPC: -150% – 194% – 220%.

Spiror machines are highly productive horizontal wrapping machines. The dimensions of the ring are adjusted to the dimensions of the products. There are versions with one and two wrapping systems.

The 4th generation of spiraling equipment has already been on the market. They are suitable for packing long objects. The operator places the object on the working surface and presses the foot key to trigger the bending. With the speed of pushing objects, it determines the level of overlapping of adjacent layers. The machine is characterized by ease of use and low price.

The 4th generation of spiraling equipment has already been on the market. They are suitable for packing long objects. The operator chooses the type of torsion, prepares the wrapping items and triggers the wrapping process by pressing the button. During pregnancy, the presence of a worker is not necessary.

Some technical data:

– diameter of the inner ring 400, 680, 960, 1200 mm;

– Wrapping and transport speeds are adjustable via Touch Screen,

– pneumatic unit for clamping and cutting of the film with a two-way cylinder,

– machine control with the ability to set up up to 20 user programs via a color touch screen,

– the choice between different wrapping cycles: wrapping of the whole object, beginning and ending, section wrapping, reinforced wrapping of the work, by-pass function;

Dimensions of the film: 125 mm wide, on a carrier 50 mm or 76 mm in diameter and max. an external diameter of 200mm, and a thickness of 17-50 μm.

ORBIT machine is more suitable for mounting in lines:

PROJECT: Formation and packaging of books and notebooks

The project contains a package for forming packages with a selected number of notes, notebooks, and transporting and packaging in a thermo-shrink film with the Athena Combi machine.

PROJECT: Packaging of laminates

The packaging is solved with the Athena CS machine with continuous welding and transport lines, the dimensions of which are adapted to the laminate.

The machine is ideal for packaging newspapers, catalogs, publications and advertising material. Its use is very simple. A protective bag is formed around the product, which machine welds and cuts according to the length of the printed matter.

Basic information and competitive advantages:

– The machine is of small dimensions and also suitable for office work (possible transport through a regular door),

– It does not need compressed air,

– The welding plate can be replaced within a few seconds,

– The machine is packed on the europallet,

– silent operation,

– Easy replacement of the film,

– Low power consumption,

– Low price.

Some parameters:

– Dimensions: 760 mm long, 1180 mm wide, 420 mm height,

– Machine weight: 100 kg, net,

– Power supply: 230V 50 Hz,

– Installed power: 500 W,

– Welding with welding wire, impulse with overheating,

– Capacity: max 50 ppm,

– Product lengths: 320 mm max, 220 – 160 mm min (depending on configured configuration)

– Product width: 245 mm max, 135 mm min (standard),

– Product thickness: 12 mm max (with appropriate guide),

– Foil: transparent or printed LLDPE, thickness 15-40u, maximum outer diameter of the roll 260 mm, maximum foil width 570 mm,

– HMI keyboard with LCD display.

PROJECT: Delivery unit

The device ensures the dosing of the semi-finished product to the machine to which it is added.

PROJECT: Tape winding machine

Machine takes plastic tape from the cutter, and wind it in the coils of the set length. After finishing the end of the tape in the coil, it drops into the box. When the number of windings is set in the box, the procedure stops until the box is withdrawn.

PROJECT: Glue dispenser

The assembly is mounted in a cardboard cutter and allows the application of cold adhesives in several places along the cardboard.

The Rotary machine is a high-class semi-automatic machine for wrapping light pallets or low-stability pallets.

There are variants for mounting on the floor and wall (W- »Wall«).

Basic technical information:

– maximum cargo dimensions 1400 x 1400 mm and height of 2000mm standard (options: 2400, 2750 mm),

– different types of foil stripping devices.

– 7 “color touch screen display, with high resolution and color icons, offers the possibility of multi-layer wrapping.

Multi-level control:

The machine’s brains are located under the control panel. The graphical display of the latest generation makes it easy to use all available functions. Functions can be easily selected at each of the six levels along the pallet height. It is possible to adjust the thickness of the wrapped film, the stretchability, the foil folding (only on the unwrapping systems of the motor-driven wrapper), the reinforced wrapping, the turning speed, the speed of the foil support, the assembly of the foil into the beam and the use of the pressure plate, and the second, options. But that’s not all. For each of the five levels, a value can be set which depends on the direction of movement of the foil carrier, which means: different for lifting and lowering. The aim here is to save foil and to reduce the wrapping cycle, which contributes to high productivity.

The Masterwrap machine creates a link between the ECOWRAP and the ROTARY machine of the lowest reputation machine.

Some technical information:

– Wrapping height up to max 2400 mm,

– The JOG control panel offers an increased number of parameters, the creation of three wrapping programs …,

– »FR« stripping equipment with electromagnetic brake.

The ECOWRAP machine is a semi-automatic wrapping machine for light unstable pallets. When it’s stationary, it is at the pillar and takes up very little space.

Technical information:

– For pallet dimensions up to 1200 x 1200 mm and maximum height 2000 mm,

– The maximum weight of the load is unlimited,

– Fixed adjustable rotational speed of the panel from 7-11 rpm and lifting and lowering of the foil carrier from 2.6 to 6 m / min,

– Automatically detects the height of the load with the photocell,

– “FRD” type system with the possibility of tightening “foil up to 100%”,

– Control panel with JOG, for quick control of machine operation,

– For foil of a thickness between 9 and 35 mm on a 500 mm high roll, with an inner diameter of 76 mm and a max. weight 6kg.